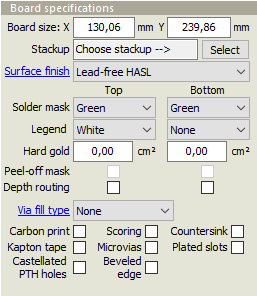

The Specs pane is used to specify board properties, such as layer buildup, surface finish, and solder mask and legend colors.

The Specs pane is used to specify board properties, such as layer buildup, surface finish, and solder mask and legend colors.

Click on the Select button to choose a buildup.

Choose a surface finish and colors for solder mask and legend. You can change the default values for these with the Configure|Options menu command.

If the board is to have hard (electrolytic) gold, specify the total area to have gold for each side.

Specify additional properties as appropriate.

If you have additional remarks that need to be passed on to the fabricator together with the production data, these can be entered either added to the Remarks layer or by using the File|Message to fabricator... menu command of the Import module.

If you are importing a board that is a revision of an existing product, you may use the Actions|Import board specs menu command and enter a product number. This will populate the board specifications and minimum feature sizes with values from the specified product.

Note: For single layer boards, it is not possible to link a soldermask file to the non-copper side of the board. In the Board Specifications pane, the soldermask color for the non-copper side will be set to None. Changing this to a color will indicate that the board should have soldermask on the non-copper side. This may increase the cost of the board.

Prototypes

Some users give their prototype versions alternate surface finish, solder mask color, and/or legend color, so that they may easily be identified as prototypes. Use the Actions|Make prototype command to assign the alternate property values to the product.

You can specify the alternate property values for prototypes with the Configure|Options menu command.