Note: This module is only available in Macaos Enterprise for Engineers.

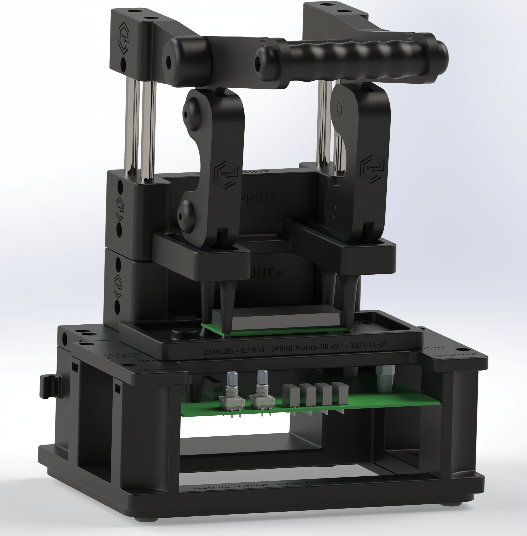

A test jig is an apparatus into which a printed circuit board assembly (PCBA) may be inserted, so that appropriate contacts may be made for in-circuit testing. Typically, the test jig holds the PCBA between an upper and lower test fixture. When the two fixtures are pressed together, spring-loaded test pins make contact with test points on the PCBA, thereby allowing test circuitry to perform an in-circuit test of the PCBA.

A test jig is an apparatus into which a printed circuit board assembly (PCBA) may be inserted, so that appropriate contacts may be made for in-circuit testing. Typically, the test jig holds the PCBA between an upper and lower test fixture. When the two fixtures are pressed together, spring-loaded test pins make contact with test points on the PCBA, thereby allowing test circuitry to perform an in-circuit test of the PCBA.

The SPRINT test jig is largely reusable. Only the test fixture "cradle" is specific to the Device Under Test (DUT).

The SPRINT test jig incorporates an upper press fixture and a base, into which the test fixture cradle is is placed. This is delivered fully assembled, with pins/receptacles installed.

The Macaos Test Fixture Designer is used to specify pin locations and generate data for manufacturing the fixture cradle.

The Test Fixture Designer module imports test pin locations, if they are included in the component layer or test pad layer of the PCBA to be tested.

Note: Do not confuse test points with test pins or test pads.

Test pads are the locations for bare-board testing of the PCB during manufacture, which are extracted from an IPC-D-356 file to the Test pads layers.

Test points are specific pads or pins on the PCBA which would be used for in-circuit testing. For each test point, a “component” (with the Test point component class) should be added to the appropriate component layer. Ideally, test points (with TPxx designators) should be included in Pick and Place data, but they may also be created manually.

Test pins are the pins in a test fixture which will make contact with the PCBA during in-circuit testing.