Introduction

Macaos Enterprise for Engineers is a powerful system for working with printed circuit boards (PCBs) and PCB assemblies (PCBAs) in real world applications, thereby simplifying your PCB/PCBA acquisition process. Whether you are part of a large organization or just a service provider in the supply chain, Macaos Enterprise for Engineers will help you get the job done.

Macaos Enterprise is not a design tool for PCBs. There are many good tools available for designing a single PCB. However, most such tools stop there. You get an excellent PCB design converted to an output format (such as Gerber and drill files) which may then be sent to a fabricator.

A single bare PCB is not a finished product. Modern electronics manufacturing makes use of automated assembly lines for component placement, soldering, depanelization, test and more. The various modules in ME for Engineers allow you to rapidly generate the data and tooling necessary for these assembly steps. ME for Engineers also eases the process of purchasing PCBs and related products.

The Macaos Enterprise System is based on products. These may be single-board PCBs, assembly array (panelized PCBs), solder paste stencils, PCBAs, test fixtures, and more. A user may only access products owned by their company or shared to them by a partner company.

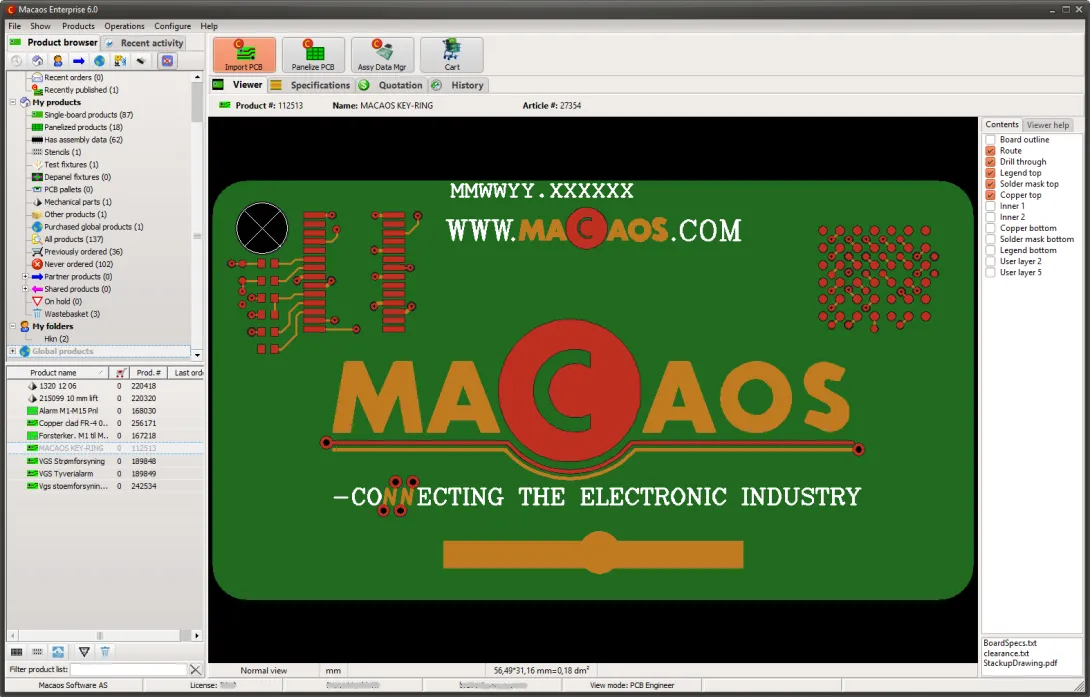

The Home view consists of three main elements:

- The left column holds the Product browser and Recent activity lists. These are used to locate an existing product.

- At the top is a button bar, giving quick access to the operations you may wish to carry out on the selected product. The available buttons depend on your selected View mode.

- The rest of the window either displays the product's graphic representation (Viewer tab), properties (Specifications tab), order/production history (History tab), or allows the user to get a price quotation for the product (Quotation tab).

Operations

ME for Engineers supports the following product operations:

- Import PCB: Import Gerber/Drill or ODB++ data to create a PCB product.

- Panelize PCB: Step up the selected PCB product to an assembly array (panel) with frame, tooling holes, fiducials, and more as desired.

- Create Stencil: Extract data from the selected PCB product to create a solder paste stencil with opening sizes and shapes tailored to your needs.

- Add mask to PCB: Add assembly related masks (such as peel-off, carbon, or hard gold) to the selected PCB product where this may be lacking from the originally imported data files.

- Assembly Data Manager: Import and manage Pick and place data and Bill of Materials lists for the selected PCB or PCBA product in a responsive, graphical environment. In this way, you can insure that component rotations are correct and that manufacturer part numbers are fully specified. Includes support for online component searches.

- Solder pallet: Design a wave solder or selective wave solder pallet for the selected PCB product. Generate a milling program to make the pallet from a sheet of appropriate material, or purchase a finished pallet.

- Depanelize PCB: This module does two things with the selected PCB Panel product: 1) Generate a milling program to remove tabs from a panel without risking damage to nearby solder joints, and 2) Design a fixture to hold the individual PCBs in place during the tab removal process.

- Test fixture: Design a test fixture for the selected PCB or PCBA product.

- Import mechanical part: Import data to create a mechanical part.